hardness test hv30|hardness comparison chart : distributors Most Vickers hardness testing machines use forces of 1, 2, 5, 10, 30, 50 and 100 kgf and tables for calculating HV. SI would involve reporting force in newtons (compare 700 HV/30 to HV/294 . 15 de mai. de 2023 · Confira os números sorteados, os ganhadores e a premiação da Lotofácil 2812, realizada em 15/05/2023, com prêmio de R$ 1.700.000,00 para 15 .

{plog:ftitle_list}

Resultado da 3,663 likes, 53 comments - caroandlace on December 13, 2022: "i don’t even know what month it is"

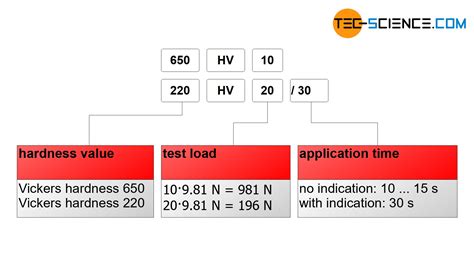

Find an explanation of how to read a Vickers hardness value (e.g. “640 HV30”), and of the meaning of the numbers and letters.It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self-deformation. A diamond in the form of a square-based pyramid satisfied these conditions. It had been established that the ideal size of a Brinell impression .

In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to . Vickers hardness testing is a common and widely used method for determining the hardness of a material. It measures the depth of penetration of a diamond indenter under .Most Vickers hardness testing machines use forces of 1, 2, 5, 10, 30, 50 and 100 kgf and tables for calculating HV. SI would involve reporting force in newtons (compare 700 HV/30 to HV/294 .The ideal hardness for automobile gears was determined to be 500 HV30. The desired hardness value, in this case, was a unitless value of 500 indented with .

vickers hardness values explained

The most commonly used indentation hardness tests for metal materials are Brinell, Rockwell, and Vickers hardness tests. The hardness value indicates a material’s ability to resist plastic deformation caused by the .This document specifies the Vickers hardness test method for the three different ranges of test force for metallic materials, including hard metals and other cemented carbides (see Table 1), .To understand the Vickers Hardness test, it is necessary to have a list of ASTM Hardness guidance related to the test. This list explains the uses, applications and scale of the test. You .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial .Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid .This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and . Prosedur Hardness Test : 1. Brinell Hardness Test. Hal yang perlu diperhatikan pada saat pengujian hardness Brinell adalah sebagai berikut : Spesimen harus memenuhi persyaratan : – Rata dan halus. – Ketebalan minimal 6 mm. – Bisa ditumpu dengan baik dan permukaan uji harus horizontal.

The Vickers hardness tester series "Qness" takes Vickers hardness testing to a whole new level. Our high-end models of the latest generation combine short cycle times with maximum precision. Features like the 8-position tool changer, comprehensive software as well as connectivity via Qconnect make this Vickers hardness tester series the optimum .Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm²; 800: 72---780: 71Practice of Micro Flexible Rolling. Zhengyi Jiang, . Haibo Xie, in Microforming Technology, 2017. 15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were .

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the .

The ideal hardness for automobile gears was determined to be 500 HV30. The desired hardness value, in this case, was a unitless value of 500 indented with a load of 30 kg for 10-15 seconds. . The Vickers hardness test was highly dependent upon the individual’s ability to measure indentations correctly. For these reasons, the operator and .

HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a relatively accurate conversion relationship between hardness and strength is needed in production.. Experience has shown that there is .Vickers hardness test is a micro testing method used for some specified cases. Sometimes it becomes necessary to change the hardness value from one scale to another. Here we compare the Vickers hardness method with the Rockwell method and their conversion charts. + 86 755 61301520; [email protected]; Search. Home;The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search.

Most Vickers hardness testing machines use forces of 1, 2, 5, 10, 30, 50 and 100 kgf and tables for calculating HV. SI would involve reporting force in newtons (compare 700 HV/30 to HV/294 N = 6.87 GPa) which is practically meaningless and messy to engineers and technicians. What is hardness? Hardness refers to the ability of a material to resist local deformation, especially plastic deformation, indentation or scratches. It is a measure of the hardness of the material. Commonly used HV=HB=HRC .It is impossible to define a single conversion method using different hardness test methods. That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables .Overview of hardness testing methods 4 3. Low-load & micro hardness testing machines − the DuraScan Series 6 4. Universal hardness testing machines − the DuraVision Series 8 5. DuraJet Rockwell hardness testing machine – flexible & versatile 10 6. ZHR Rockwell hardness tester 12 7. ecos™ III – The most efficient hardness testing .

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .The followings are the most common hardness test methods used in today`s technology: Rockwell hardness test Brinell hardness Vickers Knoop hardness Shore 3.1. Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied.Testing the hardness of steels can be used an indication of how easily they can be manipulated, (formed, machined etc.), and how they will perform mechanically. Hardness test methods. Common tests for hardness in metals involve measuring the resistance to indentation by a hardened steel or diamond ball, cone or pyramid. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness. .

The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually easier to use compared to other hardness tests. The reason is the required calculations are not dependent on the size of the indenter. .transverse section through the threaded component. Hardness testing can be carried out using Vickers, Brinell or Rockwell hardness testing as per ASTM/ISO standards. Cross-sectional hardness evalution For transverse section of the threaded component, hardness testing should be carried out as illustrated in Figure 2 within the half radius area.

The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness test follows the brinell principle, in that an indenter of definite shape is pressed into the material to be tested, then the load is removed and .Ask the Chatbot a Question Ask the Chatbot a Question Vickers hardness, a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. Devised in the 1920s by engineers at Vickers, Ltd., in the United Kingdom, the diamond pyramid hardness test, as it also became known, permitted the .

vickers hardness test explained

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The specimen size (the minimum clearances between test points (indent spacing) and from the specimen edge (edge clearance) for Vickers defined in the standard must be observed); The specimen thickness (the specimen thickness must be at least 1.5 times the indentation diagonals, i.e. the minimum specimen thickness must be between 0.085 and 6.5 mm); The surface .

vickers hardness test diagram

vickers hardness test chart

test if canning jars are sealed lift by lid

WEB25 de set. de 2023 · Ninguém acertou as cinco dezenas sorteadas hoje no concurso 6250 da Quina. O que aconteceu: Os números sorteados foram 01-45-53-77-78. .

hardness test hv30|hardness comparison chart